At Chimi, we have an integrated process to customize your EVA case.

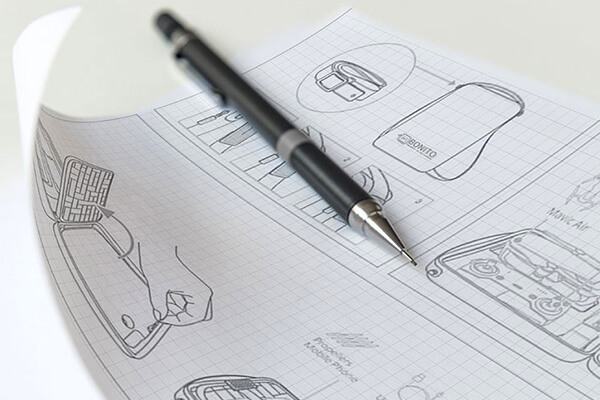

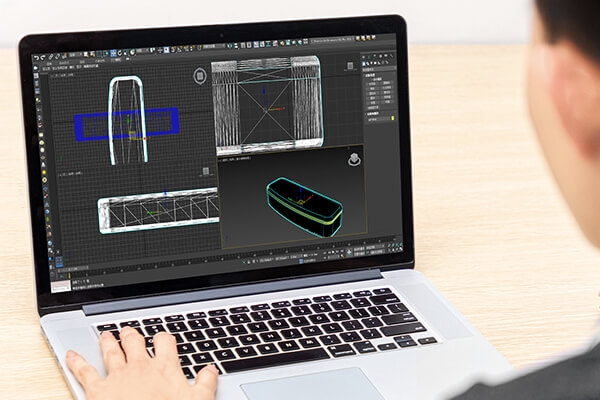

Our approach starts with the design. Whether you have a sketch, CAD file, prototype sample, or you need us to design a custom case from scratch, we have it covered.

With our advanced facility and experienced personnel, we’ll take care of the EVA case tooling, prototyping, production, and delivery. Our full services ensure that you’ll receive zero-defect eva cases just in time.

Our all-in-one process makes your experience with Chimi Case as smooth as possible and allows you to focus on your core business.